Heat protection: Muffler heat shield can protect nearby components from heat damage by reducing the amount of heat that radiates from the exhaust system.

Improved performance: By reducing the amount of heat that radiates from the exhaust system, muffler heat shield can help improve the performance of nearby components, such as the engine or transmission.

Increased durability: Muffler heat shield can help increase the durability of nearby components by reducing the amount of heat-related stress they experience.

Enhanced safety: By reducing the amount of heat that radiates from the exhaust system, muffler heat shield can help reduce the risk of fire or other safety hazards.

Overall, using muffler heat shield can help improve the performance, durability, and safety of a vehicle or other machinery.

What Is Heat Shield

In engineering, a heat shield is a component designed to protect an object or a human operator from being burnt or overheated by dissipating, reflecting, and/or absorbing heat. The term is most often used in reference to exhaust heat management and to systems for dissipating frictional heat. Heat shields are used most commonly in automotive and aerospace.

Radiant Heat Shields: Radiant heat shields are designed to reflect heat energy away from the shielded component. They are commonly used in automotive applications to protect the engine and exhaust system. Radiant heat shields absorb very little heat and are usually made of thin, lightweight materials such as aluminum foil or ceramic tiles.

Conductive Heat Shields: Conductive heat shields are designed to absorb heat energy and dissipate it away from the shielded component. They are commonly used in electronic applications to protect sensitive components from heat damage. Conductive heat shields are usually made of materials with high thermal conductivity, such as copper or aluminum.

Convective Heat Shields: Convective heat shields are designed to create a flow of air around the shielded component, dissipating heat energy away from the component. They are commonly used in aerospace applications to protect against heat generated during re-entry into the Earth’s atmosphere. Convective heat shields are usually made of materials that can withstand high temperatures, such as ceramic or carbon fiber.

Active Heat Shields: Active heat shields are designed to actively cool the shielded component by using a cooling system, such as a liquid cooling system or a refrigeration system. Active heat shields are commonly used in high-temperature applications such as rocket engines and industrial furnaces.

Heat shields play a critical role in many applications, protecting against heat damage and increasing the lifespan of surrounding components. They are designed to withstand high temperatures and can be customized to fit specific applications. The choice of heat shield material and type depends on the application’s operating environment, temperature range, and required performance.

In summary, heat shields are essential components that protect against heat damage in various applications. They work by either reflecting, absorbing, or dissipating heat energy, depending on the type of heat shield used. With a wide range of materials and types available, heat shields can be customized to fit specific applications, protecting the surrounding components and increasing their lifespan.

Heat shields are critical components used for thermal management in a wide range of applications, and their purpose doesn’t tend to vary much from market to market—whether they are used on a car or a spacecraft.

Essentially, a heat shield is a thermal barrier designed to protect objects from overheating. In the automotive sector, they are typically used to isolate the engine block to prevent heat damage to bodywork and internal components. They can also provide performance enhancements by reducing under-hood heat and intake air temperature (IAT), which is key for optimal engine performance.

In this article, we will explore some of the different types of heat shields and the materials used in their construction. We will also take look at conventional heat shield materials versus more innovative solutions.

There are two main kinds of heat shields for cars: fixed, or rigid components; and flexible components. A rigid heat shield might be fabricated from solid steel, but given the additional weight and subsequent loss of performance, aluminum sheet is preferable. Aluminum can also be used for flexible heat shields which are more conformable and lighter weight. Conventional wisdom associates thicker, denser materials with greater thermal capacity, but precision thermal coatings have enabled engineers to leverage a wide range of materials for thermal barrier applications.

Thermal textiles are increasingly used for automotive insulation, mainly for exhaust systems and cabin insulation. But high-temperature fabrics comprised of fiberglass or silica with proprietary coatings can also be used for thermal barriers in engine environments. These novel heat shields combine the extreme heat resistance of ceramic coatings with the conformability of thin sheeting, yielding an optimal solution for lightweight heat shielding in automotive applications.

One of the benefits of fabricated heat shields is the reduction of engine block weight which contributes to greater fuel efficiency, faster acceleration, and so on. Their increased formability also makes it easier to shield specific components from under-hood heat, such as the air intake system. By reducing the IAT, engineers can effectively prevent long-term performance reductions associated with temperature-induced engine timing variations. Similar benefits can be obtained by shielding engine mount vents too.

Heat shields are used in various applications across different sectors to protect against high temperatures and prevent heat damage. Some of the most common applications of heat shields are in the automotive, aerospace, and industrial sectors.

Automotive Sector

In the automotive sector, heat shields are commonly used to protect the engine, exhaust system, and other components from high temperatures generated during operation. For example, the exhaust system generates high temperatures that can damage the surrounding components and even ignite nearby materials. To prevent this, heat shields are used to reflect or absorb the heat energy. Similarly, heat shields are used to protect the engine from high temperatures generated during operation. Heat shields are also used in the brake system to prevent brake fade caused by high temperatures.

Aerospace Sector

In the aerospace sector, heat shields are used to protect against high temperatures generated during re-entry into the Earth’s atmosphere. During re-entry, the spacecraft generates high temperatures due to the friction between the atmosphere and the spacecraft’s surface. To prevent heat damage to the spacecraft and the crew, heat shields are used to absorb or dissipate the heat energy. For example, the heat shield on the Apollo spacecraft was made of a material called Avcoat, which was designed to absorb heat energy by melting and evaporating.

Industrial Sector

In the industrial sector, heat shields are used to protect against high temperatures generated during various processes. For example, heat shields are used in furnaces to protect the surrounding components from high temperatures generated during the heating process. Heat shields are also used in the oil and gas industry to protect the pipelines from high temperatures generated during the transportation of oil and gas. In addition, heat shields are used in the chemical industry to prevent heat damage to the surrounding components during various chemical processes.

When choosing a heat shield, several factors need to be considered to ensure that the right heat shield is selected for the specific application. Some of the factors to consider when choosing a heat shield include the application, operating temperature range, and material.

Application

The first factor to consider when choosing a heat shield is the application. The type of heat shield required will depend on the application’s specific needs, such as the location and type of heat source and the components that need to be protected. For example, in the automotive sector, a heat shield designed to protect the engine may not be suitable for use in the brake system.

Operating Temperature Range

Another critical factor to consider when choosing a heat shield is the operating temperature range. Heat shields are designed to withstand high temperatures, but each heat shield has a specific temperature range that it can operate within. The temperature range of the heat shield must be compatible with the application’s operating temperature range to ensure that the heat shield can effectively protect the components.

Material

The material used to manufacture the heat shield is also an essential consideration when selecting a heat shield. Different materials have different properties that affect their performance, such as thermal conductivity, weight, and cost. The choice of material will depend on the application’s specific needs and requirements, such as the level of heat protection required, the weight of the heat shield, and the cost.

1. Research the application’s specific needs and requirements to determine the type of heat shield required.

2. Consider the operating temperature range of the application and select a heat shield capable of withstanding the required temperature range.

3. Choose a material that has the required properties for the specific application, such as thermal conductivity, weight, and cost.

4. Consult with a heat shield manufacturer or supplier to ensure that the selected heat shield is suitable for the application and meets all necessary requirements.

5. Consider the installation requirements of the heat shield, such as the size, shape, and attachment method, to ensure that the heat shield can be installed correctly.

In summary, selecting the right heat shield for a specific application requires careful consideration of factors such as the application, operating temperature range, and material. Tips for selecting the right heat shield include researching the specific needs and requirements of the application, choosing a material with the required properties, and consulting with a heat shield manufacturer or supplier. By selecting the right heat shield, it is possible to protect against heat damage and improve the efficiency and safety of the application.

Ningjin Zhiyuan New Material Co., Ltd. was established in 2002, mainly committed to the development, production and sales of sound-cancelling, heat insulation and high performance heat resistant fiber products.

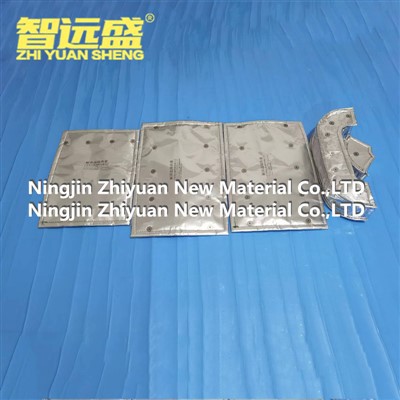

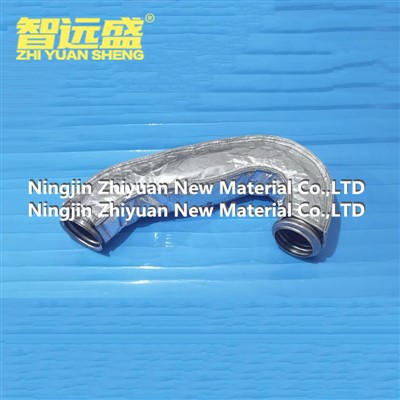

The main products: Fiberglass sound insulation cotton, Fiberglass pipe (Glass Fiber Tube), fiber Glass molded parts, basalt fiber sound insulation cotton, Fiberglass Needle Mat, basalt fiber Needle Mat, Fiberglass Heat Shield mat, basalt fiber Heat Shield mat, basalt fiber tube, basalt fiber strip, muffler Heat Shield, exhaust Heat Shield, Turbocharger Parts Heat Shield, purifier Heat Shield, Battery insulation cover, Generator Heat Shield, Engine sound insulation cotton, wiring harness Heat Shield, oil tube Heat Shield, fuel tank Heat Shield, Generator unit Heat Shield ETC.

Q: What does a heat shield do?

Q: Can you drive without a heat shield?

Q: Is it OK to remove the heat shield?

Q: How much does it cost to replace a heat shield on a car?

Q: What happens if heat shield goes bad?

Q: What is the best thing to use for a heat shield?

Q: What holds a heat shield on?

Q: Do I need a heat shield on my catalytic converter?

Q: Do heat shields really work on cars?

Q: What is the heat shield hanging off my car?

Q: Does a gas tank need a heat shield?

Q: Why did my heat shield fall off?

Q: What causes a heat shield to fall off?

Q: Is a heat shield expensive to fix?

Q: Does the heat shield cover the catalytic converter?

Q: How do you know if your heat shield is loose?

Q: How long should a heat shield last?

Q: What material can be used as a heat shield?

Q: What temperature does the heat shield have to withstand?

Q: Do I need to replace the heat shield under my car?

We're well-known as one of the leading heat shield manufacturers and suppliers in China. Please feel free to buy customized heat shield at low price from our factory. For quotation, contact us now.

Basalt Fiber Silencer Cotton, Basalt Fiber Silencing and Heat Insulation Cotton, Engine Muffler Heat Shield